Strona główna » Laboratory

Laboratory

Our laboratory performs analysis in accordance with Quaker Chemical procedures and is specialized in testing the parameters of processing fluids. The laboratory is equipped with state-of-the-art equipment that allows us to reliably determine the condition of coolants in a quick manner. We perform basic analyses and packages to determine the condition of emulsions.

We analyze:

Elevated pH can cause skin problems in workers, corrosion of non-ferrous components, among other things. On the other hand, lowered pH contributes to the growth of microorganisms, reduced emulsion durability and iron corrosion.

We obtain information on the anticorrosive effect, bacteriological stability of the emulsion. Elevated concentrations result in viscous contamination, increased machining agent consumption, foaming problems, and increased risk of skin problems. On the other hand, a reduced concentration has a negative effect on emulsion stability, tool wear and causes corrosion problems.

Provides information on the lubricating and anticorrosive effects of emulsions.

A high content of foreign oil and free foreign oil can lead to sludge formation and the growth of bacteria and fungi, and negatively affect grinding and machining performance. A negative foreign oil result indicates a loss of oil in the emulsion.

Elevated levels can lead to the formation of insoluble precipitates, reduced corrosion protection, loss of process efficiency, and emulsion instability (delamination).

Elevated levels can lead to the formation of insoluble precipitates, reduced corrosion protection, loss of process efficiency, and emulsion instability (delamination).

Bacteria and fungi multiply in the boundary layer between the foreign oil and the emulsion. A large number of colonies of bacteria, fungi/yeast leads to unpleasant odors, clogging of installations, filtration problems, reduced emulsion durability, lowered pH and skin problems in workers.

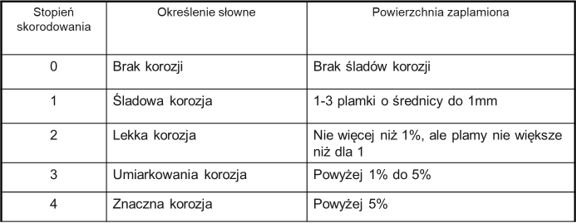

Corrosion indicates improper quality of machining fluid.

Ford corrosion

Knowledge of water parament is essential when selecting the right type of coolant.

We determine Hardness: calcium, magnesium and total, pH conductivity, chlorides, microbial contamination of water – dipslides

Recommended water parameters for emulsions:

pH- approx.7

conductivity mS/cm – 1-1,5

total hardness odH – 5-20

chlorides ppm – 100

bacteria / fungi – 10 2

The ratio of calcium and magnesium ions in water indicates the quality of cutting fluids, their tendency to foam, and the formation of insoluble soaps

Nitrites and nitrates are harmful to the human body. Their test is used to indirectly determine nitrosamines, compounds dangerous to human life.

The presence of these substances in the coolant, should be controlled, for example, through the use of strip test indicators

The test involves immersing a strip in the coolant, at the end of which is applied an indicator that changes color, depending on the concentration of nitrites.

Monitor coolant parameters:

You care about the health of your employees

You care about the quality of workpieces and tools

You save

Report the implementation of the service

Contact us for a customized offer