Magnetic roller filters

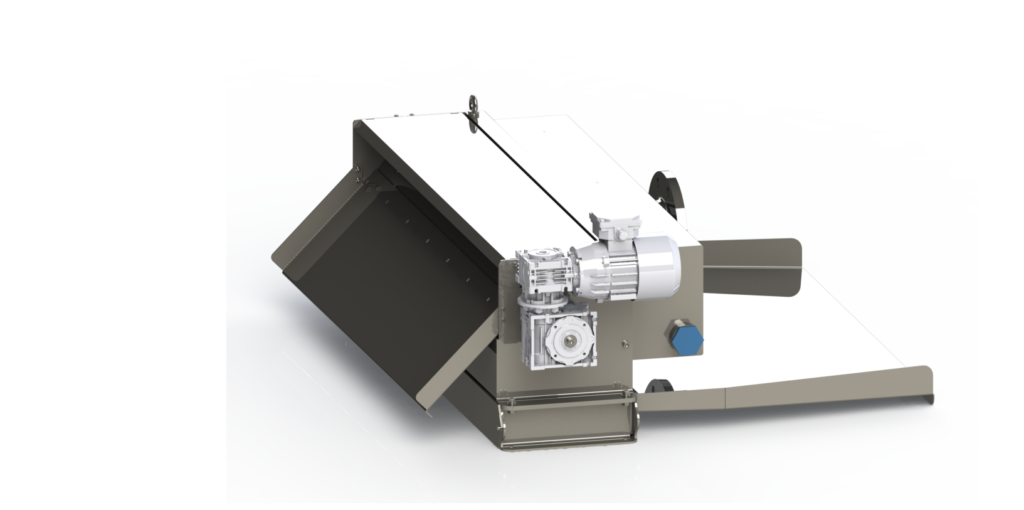

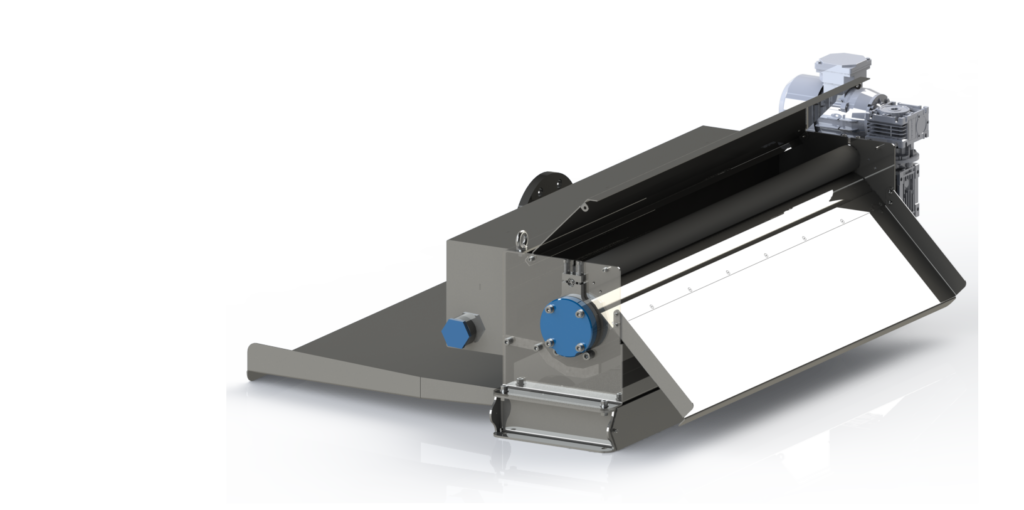

The magnetic separator is used to filter ferromagnetic chips/particles from the coolant. The filtration accuracy of the magnetic separator varies, depending on the material to be processed as well as the particle size, up to a maximum of 2 microns. It can be used in the installation of central filtration systems as well as in individual machines.

The operating principle of the device is based on a rotating magnetic core. The coolant is fed to the magnetic core by means of a pump or by gravity. When ferromagnetic particles come into contact with a magnetic field, they are attracted and then separated. Contaminants are transferred outside the system.

We have 2 types of magnetic filters, depending on the process:

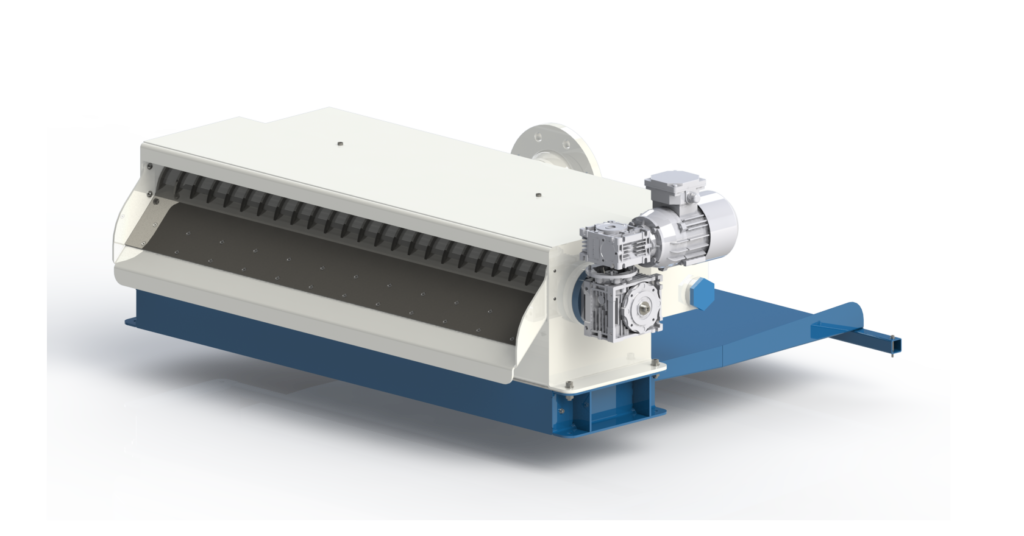

Magnetic disk separator (SMD)

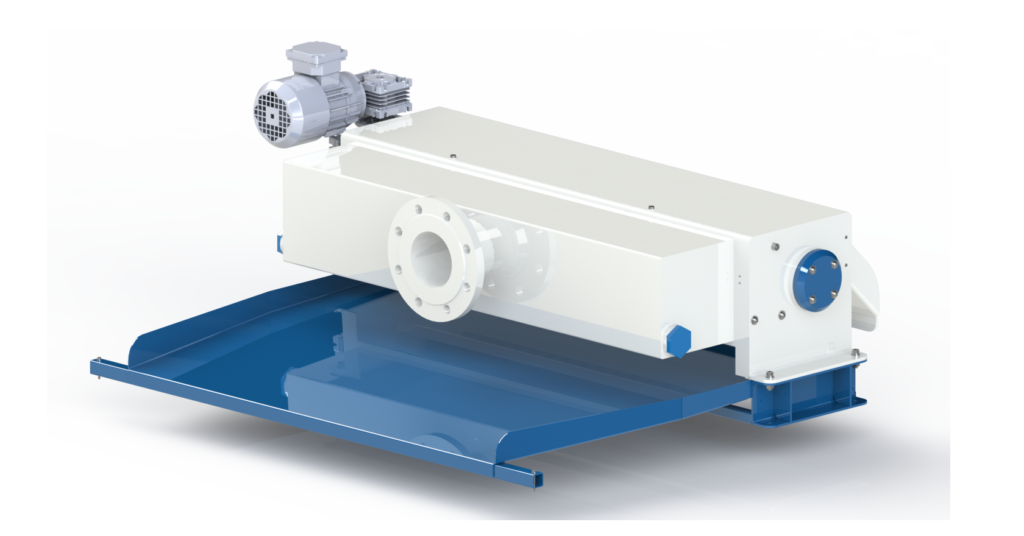

Smooth shaft magnetic separator (SMG)

Technical details

SMG Type

| Unit | SMG-300 | SMG-400 | SMG-500 | SMG-600 | SMG-700 | SMG-800 | SMG-900 | SMG-1000 | |

|---|---|---|---|---|---|---|---|---|---|

| Flow | L/min | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height | mm | 449 | 449 | 449 | 449 | 449 | 449 | 449 | 449 |

| Length | mm | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

| Width | mm | 659 | 864 | 905 | 987 | 1028 | 1110 | 1192 | 1233 |

| Flow | DN | 65 | 80 | 100 | 100 | 100 | 100 | 100 | 100 |

SMD Type

| Unit | SMD-300 | SMD-400 | SMD-500 | SMD-600 | SMD-700 | SMD-800 | SMD-900 | SMD-1000 | |

|---|---|---|---|---|---|---|---|---|---|

| Flow | L/min | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height | mm | 449 | 449 | 449 | 449 | 449 | 449 | 449 | 449 |

| Length | mm | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

| Width | mm | 659 | 864 | 905 | 987 | 1028 | 1110 | 1192 | 1233 |

| Flow | DN | 65 | 80 | 100 | 100 | 100 | 100 | 100 | 100 |